Contact Us

PAMID D650

- Commodity name: PAMID D650

- Details

-

Application system:

Especially developed for room temperature curing epoxy primer, mainly used for heavy-duty anti-corrosion paint and ship paint. Such as: epoxy primer, chlorine rubber and alkyd system. It has excellent anti-sinking, anti-sag properties and good recoatability (no inter-layer adhesion problems).

Features:

PAMID D650 is a high-performance micronized amide wax thixotropic agent.

Specific performance:

- 100% active ingredients, excellent cost performance

- Shear force change/viscosity restores a good balance, which can achieve good leveling of the coating film

- Very good re-coatability

- Very good anti-sagging effect

- Long-lasting anti-settlement effect

- Good storage stability

Physical properties:

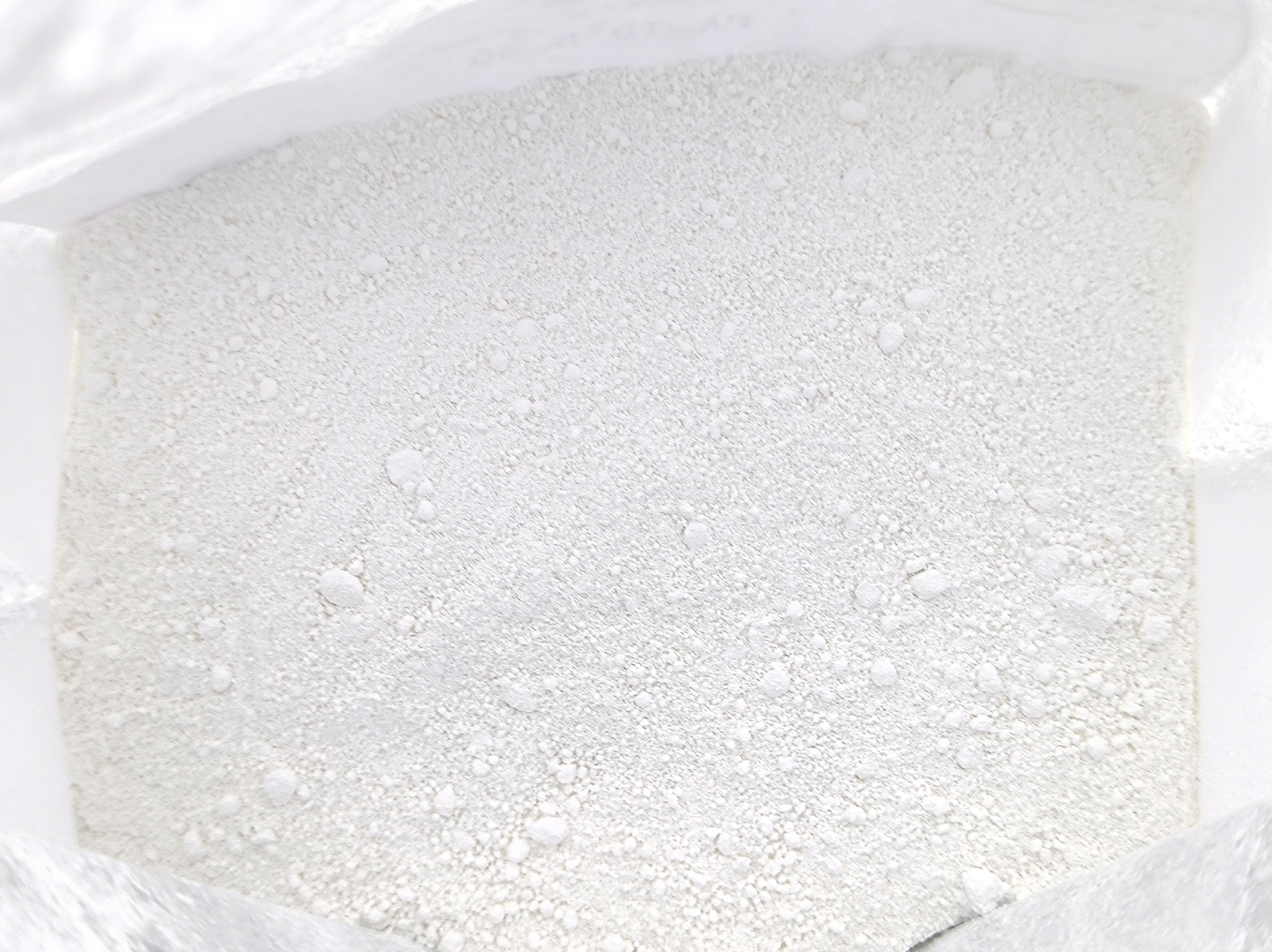

Appearance: white powder

Particle size distribution: 90%<0.5 μm

Melting point: 120-130°C

Compared with traditional organic wax rheological agents, PAMID D650 overcomes the shortcomings of reverse coarseness, false thickening and precipitation.

Recommended addition level: 0.5 - 1.5%

How to use:

Use a high-speed disperser/or sand mill to generate appropriate temperature and shear force, so that PAMID D650 can achieve good dispersion and activation effects.

PAMID D650 is best added together with the resin during the pigment dispersion and grinding stages. During the dispersion process, the temperature can be effectively activated by raising the temperature to 55°C, but it is best to be between 65-75°C; and maintain it for 60 minutes. For complex formulations and application conditions, we strongly recommend rigorous testing prior to use. Especially under poor applicable conditions such as: hot substrate, thermal spray, etc.。

Storage temperature:

A dry place between 5°C and 30°C.

Shelf life:

Two years.

Precautions:

Avoid direct contact with sunlight.

For additional safety information please see the Safety Data Sheet。

The information described in the above documents is based on data from our experimental center and related literature; we do not assume corresponding legal liability. Our ordinary standards impose only limited obligations. Consistent with local laws and regulations, our company assumes no responsibility for the handling, processing or use of this product.

Key words:

Application industry

The paint industry

Ink industry

The nanomaterials

Sealing material

Energy industry

Electronic materials

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

SAF Coolest v1.3.1.2 设置面板 GQYSD-ZROR-GAZDE-AXQ

V1.3.1 SVG图标库请自行添加图标,用div包起来,并命名使用

Feedback

Quick Navigation

Contact Us

Email: jason@corechemie.com

TEL: 86-020-87223588

Address: 9/F,Unit 1, Runcheng Science and Technology Park,

Zengcheng,Guangzhou,Guangdong,China

Copyright © 2023 Corechem Corporation Holding Co.,Ltd